Part One of our five part series, ‘Measuring, Marking & Layout for Beginner Woodworkers‘

Beginning woodworkers often believe that good results come from good cutting—sharp saws, steady hands, and careful technique. While those things matter, most woodworking mistakes happen before the blade ever touches the wood.

They happen during measuring, marking, and layout.

This series will show you how experienced woodworkers think about accuracy, why layout is a skill rather than a step, and how simple habits can dramatically improve your results—even with basic tools.

The Hidden Foundation of Good Woodworking

In woodworking, cutting is permanent. Measuring and marking are where you decide what will be permanent.

If a joint doesn’t fit, a shelf is out of square, or a project feels “off” even though nothing looks obviously wrong, the cause is almost always layout—not execution.

Good layout:

- Reduces cumulative error

- Keeps parts consistent

- Makes joints fit naturally

- Allows hand tools to work at their best

Poor layout forces you to “fix” problems later, often by removing more material than you intended.

Measurement Is Not the Same as Accuracy

Beginners often chase precision by reading numbers carefully. Experienced woodworkers chase accuracy by controlling references.

Two important ideas to understand early:

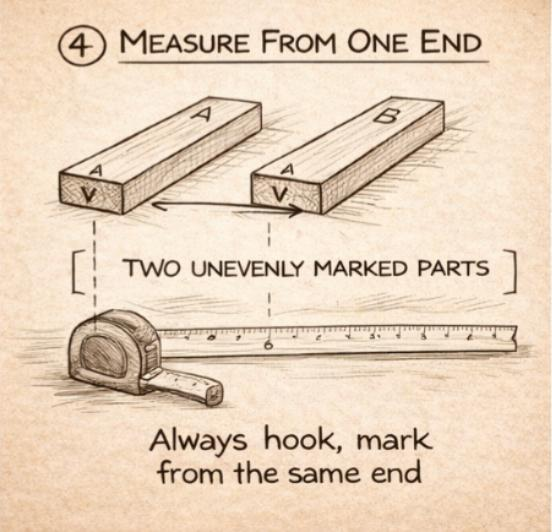

1. Numbers Are Less Important Than Consistency

If two parts must match, it’s better to mark both from the same reference edge than to measure them separately—even if your measurement is “perfect.”

Woodworking tolerates small numerical errors remarkably well, but it punishes inconsistency

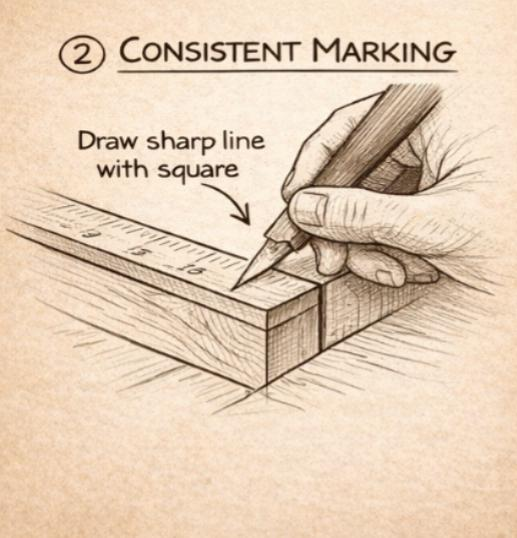

2. Layout Lines Matter More Than Measurements

Measurements tell you where something should be.

Layout lines tell you where to cut.

A clean, intentional line—made with the right tool and referenced properly—is more valuable than a tape measure read down to the 64th.

Why Layout Is a Skill, Not a Step

Layout is where design becomes physical. It is where you:

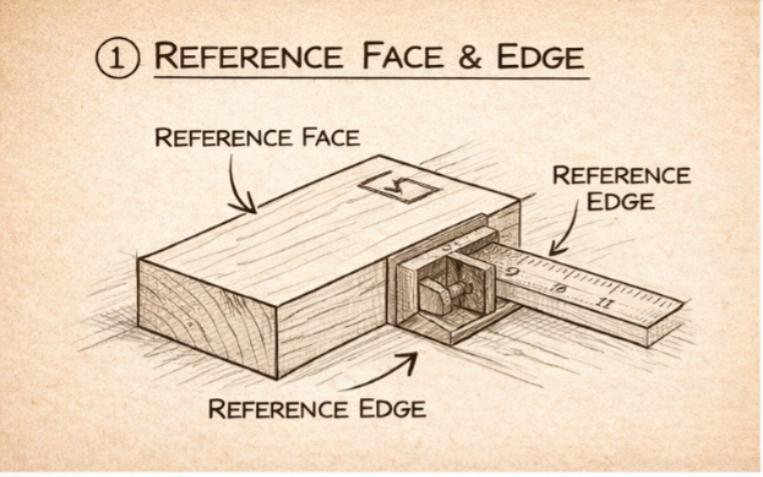

- Choose reference faces and edges

- Decide how parts relate to one another

- Translate drawings into real dimensions

- Anticipate joinery and assembly

Good layout slows you down in the right way. It gives you time to think, correct, and confirm—before anything irreversible happens.

This is especially important for beginner projects, where small errors compound quickly.

The Core Tools of Measuring & Marking

You do not need many tools to work accurately, but the ones you use must be used correctly. Over this series, we’ll cover tools like:

- Tape measures and rules

- Combination squares

- Marking knives and pencils

- Gauges, dividers, and story sticks

More importantly, we’ll cover how and when to use each one—and when not to.

What This Series Will Cover

In the posts ahead, you’ll learn:

- How to choose and use reference edges

- Why marking knives outperform pencils for joinery

- How to avoid cumulative measuring errors

- Simple layout strategies for frames, shelves, and boxes

- How professionals “measure without measuring”

Each post builds on the last, reinforcing habits that will serve you for every project you build.

Start Thinking Like a Woodworker

Good woodworking doesn’t begin at the saw.

It begins at the bench, with a square, a marking tool, and a clear plan.

By learning to measure, mark, and lay out your work deliberately, you’ll find that cutting becomes easier, joints fit better, and your projects start to feel intentional instead of improvised.

In the next post, we’ll start with the most important—and most misunderstood—concept in layout: reference faces and reference edges.